In the global marketplace, there are few companies which have mastered the production technology of combining co-extrusion barrier film and custom printed flexible packaging. Huafeng is one of them! Combining co-extrusion barrier film and custom printed flexible packaging together helps creates the best of all plastic materials. We don’t stop here, however, Huafeng keeps developing new high-tech products to meet diverse requirements from customers. These products all enjoy small oxygen transmission rate, which is less than 0.8%.

Huafeng possesses many advanced film blowing machines, including multi-layer co-extrusion film blowing machines (upper-driving rotating), seven-layer film blowing machines (down-driving rotating) and seven-layer cast stretch film co-extrusion lines. These machines provide a yearly production of 12,000T.

Huafeng is equipped with 4 high-speed rotogravure printing machines, which will print 10,000T of products. This is where the plastic film gets colored. When utilizing eco-friendly printing ink, our printing machine provides high-quality products with delicate patterns. When placed on a merchandising rack, it could help to attract customers’ attention.

Huafeng’s operates both a dry lamination workshop and no-solvent lamination workshop. Each of them supports an annual lamination capacity of 20,000T.

Our custom printed flexible package making workshop and storage bag making workshops are equipped with diverse production machines, which possess different machining widths. In addition, these machines feature high efficiency and high-quality production, providing “perfect” packaging bags. With these machines, our bags possess attractive appearance, good gas-tightness, high strength and diverse shapes. Therefore, they can be applied in almost every area of the flexible packaging industry.

Huafeng’s EVA film making workshop possesses various automatic production equipment. The EVA film manufactured in the workshop possesses a small shrinkage ratio lower than 2% and a 25 year service life under a hot and humid environment.

Our air bubble fill extrusion lines and many other advanced production machines make Huafeng a fully equipped manufacturer, which provides many benefits for new products’ development.

Huafeng always places customers' preference and convenience as our top priority, which leads to the supply of high-quality packaging bags and one-stop-service for our customers, from the plastic particle’s supply to the product's delivery. In this way, our products’ quality is well guaranteed.

Raw material workshop covers an area of 5,000 square meters, and all the raw materials stored in the workshop are new materials, which feature eco-friendly and food-grade. Besides that, Huafeng’s raw material workshop enjoys a stable supply chain.

Raw material workshop

Raw material workshop

EVA production workshop is outfitted with various automatic production equipment, which enable online detection. Online detection highly assures an even thickness of EVA film, a small shrinkage ratio lower than 1%, crosslinking degree of 85%, fast lamination and 25 year’s serving life under hot and humid environment.

EVA (Ethylene vinyl acetate) production workshop

EVA (Ethylene vinyl acetate) production workshop Finished EVA film packaging

Finished EVA film packaging

In solventless lamination workshop, there are two solventless laminators, which support an annual production capacity of 20,000T. Meanwhile, products manufactured with solventless laminator enjoy high lamination strength and no residual solvent. Therefore, diverse materials could be laminated here, especially for food packaging bags.

Solventless lamination workshop

Solventless lamination workshop High-speed production with solventless laminator

High-speed production with solventless laminator

Huafeng has 6 dry lamination lines, which supports an annual lamination capacity of 20,000T. Meanwhile, the lamination line allows for PVOH (polyvinyl alcohol) coating. After dry lamination, barrier materials with gas permeability lower than 1% could be laminated.

Dry lamination workshop

Dry lamination workshop

7-layer cast stretch film co-extrusion line could be used to co-extrude diverse resins, such as EVOH (Ethylene vinyl alcohol), PA (polyamide), PP (Polypropylene), PE (Polyethylene) and so on. With the equipment, the strengths from diverse plastic materials are combined together, which well avoids the generation of residual solvent during lamination of two materials with glues.

Seven-layer cast stretch film co-extrusion line

Seven-layer cast stretch film co-extrusion line Side view of cast stretch extrusion line

Side view of cast stretch extrusion line

Air bubble film extrusion line could be used to manufacture bags with different air bubble dimensions (φ5mm-φ40mm). Meanwhile, different printed flexible materials could be mounted on the surface of air bubble films, such as kraft papers, PE films, expanded polyethylene, metalized PET films and etc. The design allows for an anti-vibration protection towards interior products.

Air bubble film extrusion line

Air bubble film extrusion line

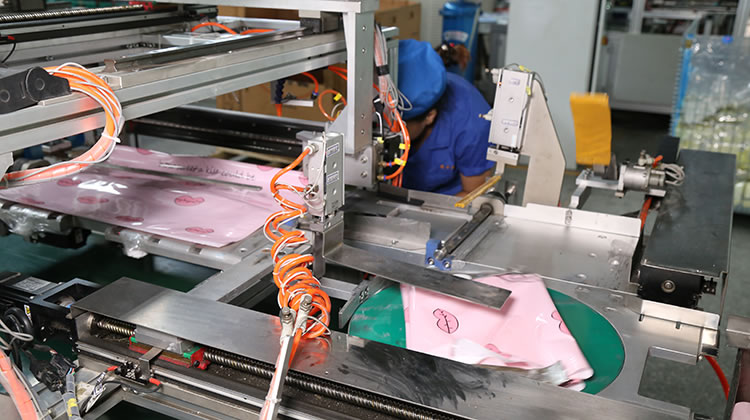

Huafeng possesses four rotogravure printing machines, which enables an annual production capacity of 10,000T. The printing machine features high overprinting accuracy, good image representation effect and etc. Besides that, when adopts eco-friendly printing ink, such as alcohol-water plastic composite ink and so on, the printing machine could help to provide high-quality products without any residual solvent. When placed on merchandizing rack, it could help to attract customers’ attention.

High-speed rotogravure printing machine

High-speed rotogravure printing machine Receiving zone of rotogravure printing machine

Receiving zone of rotogravure printing machine Finished film with delicate patterns

Finished film with delicate patterns

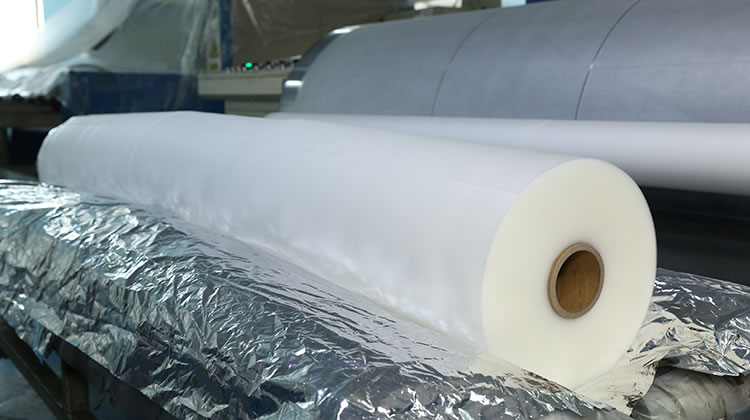

Huafeng possesses six multi-layer co-extrusion blown film lines, which enable an annual thin film production capacity of 12,000T. Thin films manufactured with multi-layer blown film lines are of high transparency, high tensile strength, uniform thickness and etc.

Huafeng is dedicated itself to producing functional thin films, which features easy opening, anti-fogging, mildew-proof, anti-biosis, anti-static and etc.

Co-extrusion upper blown film workshop

Co-extrusion upper blown film workshop Finished thin film after upper blown

Finished thin film after upper blown

Co-extrusion upper film blown workshop has more than a dozen of multi-functional high-precision bag making machines, which could produce almost 2 billion bags, including three-side seal plastic bags, four-side seal plastic bags, custom fin seal paper bags, plastic stand up pouches, zipper storage bags, special shaped bags, flat poly bags and etc. All the bags manufactured in Huafeng possess attractive appearance, good gas-tightness, high strength and so on. Therefore, they could be used in almost every area of flexible packaging industry.

Custom printed flexible package making workshop

Custom printed flexible package making workshop Automatic high-precision bag making machine

Automatic high-precision bag making machine Color mark sensor for cut-to length detection

Color mark sensor for cut-to length detection Finished flexible package

Finished flexible package

Huafeng is one of the world leading vacuum seal storage bag manufacturers, which possesses over 20 pieces of bag making machines and automatic bag folding machines. These machines support an annual production capacity of 200 million pieces of vacuum seal storage bags. These vacuum seal storage bags feature small rate of gas permeability, attractive appearance and multi-functional. Besides that, Huafeng also established a trackable system for barcode management, which helps to establish an leading brand in global vacuum seal storage bag making fields.

Storage bag making workshop

Storage bag making workshop Automatic bag folding line

Automatic bag folding line Automatic capping

Automatic capping Cutting zone

Cutting zone

Vacuum seal storage bag packaging workshop is highly automatic, which possesses a dedicated packaging team. Its members could produce 800,000 pieces of bags in a single day, ensuring that the finished products being delivered within 24 hours.

Storage bag packaging workshop

Storage bag packaging workshop

Finished product warehouse covers an area of 6,000 square meters. At the same time, FIFO system (first-in, first-out) is adopted in our finished product warehouse, and all the items are trackable.

Finished product warehouse

Finished product warehouse

Huafeng’s bags also have a high popularity in overseas market. When it comes to the day for product exportation, there are always one or more than one containers’ of goods. Huafeng’s products could be exported from Port of Ningbo and the port of Shanghai. When we deliver products by ships, we will always adopt many protective measures, such as moisture-proof measure, anti-vibration measure, anti-tilting measures and others to ensure the security of our products.

Container loading

Container loading Product delivery

Product delivery

Ningbo Huafeng Package Co., Ltd.

Add.: No.106 Jinhan Rd., Yuyao industrial park, Zhejiang Province, China

Contact person: Mr. Chen

Tel: +86-574-62273668

Fax.: +86-574-62273628

E-mail: nbhfbz@188.com